These are the steps of the craft

Prepare The Pattern

The pattern is traced onto cardstock and cut out with special shears that cut a space between the pieces to allow for the foil on the glass.

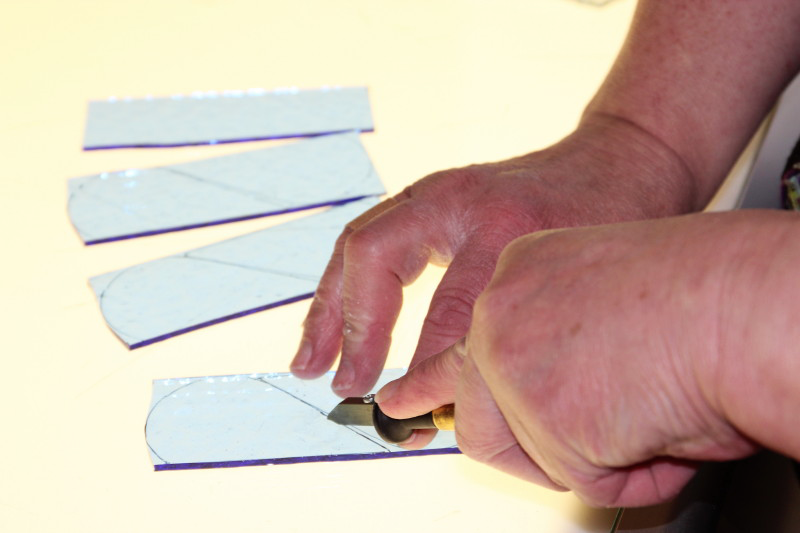

Cut Out The Pattern Pieces In Glass

The pattern pieces are traced with marker onto the glass and cut with a glass cutter. Or, sometimes the pattern pieces are directly attached to the glass and then cut. The glass cutter has a special hard wheel that will make a score (like a scratch) on the glass. Then when you try and “bend” the glass where you want it to break, it should break along the score line. This doesn’t always work!

The edges of the glass are very sharp at this point and it may be jagged. The glass piece may not be the same size and shape as the pattern piece.

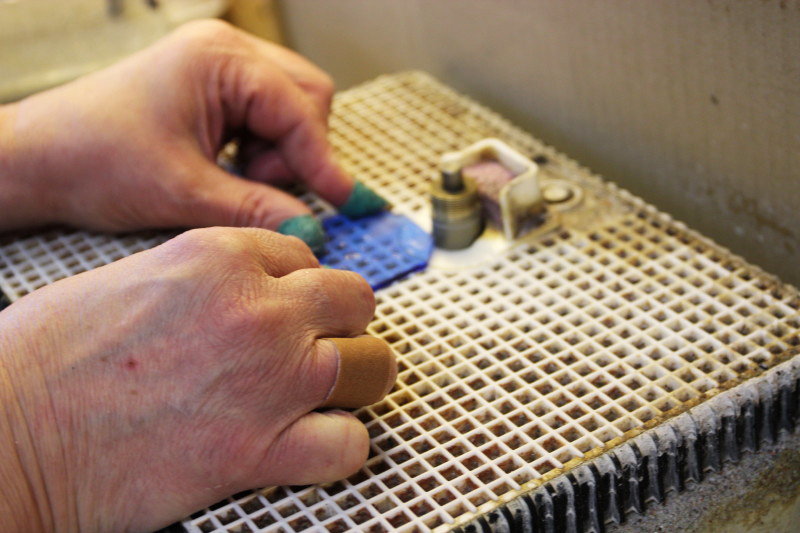

Grind The Glass

The glass pieces are ground on a grinder with a diamond-encrusted bit to smooth the edges and shape the piece exactly to the pattern. This can also be done by hand with a special stone but can take a very long time.

Foil The Glass

The glass is now wrapped in copper foil and the edges crimped around the piece. This foil comes in different widths, thicknesses and different coloured backings to suit the different types of glass and the way you want your final project to look. The glass needs to be wrapped in copper so that the solder has something to stick to so you can hold your project together.

Burnish The Copper Foil

The edges of the copper around the glass must be pressed down tightly against the glass before it can be soldered. This is called burnishing and it is most often done with a tool called a fid or lathekin, but lots of things can be used.

Solder The Glass Pieces Together

The glass pieces are now stuck together with solder. Different types of solder can be used depending on the project. The jewelry and coasters here are put together with a lead-free solder containing 97% tin and 3% copper.

Patina And Finish The Project

The project is cleaned, the colour of the solder changed with a patina if desired, then the piece is treated and polished with a finishing compound. This finishing compound helps to slow oxidation and discoloration of the solder.